Ntev Table tuav Steel Material Railway Transfer Cart

piav qhia

Cov yam ntxwv ntawm kev tsheb ciav hlau hluav taws xob hloov tsheb feem ntau suav nrog kev ua haujlwm zoo, kev siv nyab xeeb, kev saib xyuas yooj yim, kev thauj khoom loj, tsis muaj kuab paug, tsis muaj suab nrov, tsis muaj kev cuam tshuam los ntawm kev siv hluav taws xob luv luv, kev txhawb nqa kev ua haujlwm zoo, cov roj teeb loj, lub neej ntev, thiab tuaj yeem ntsia tau rau ntawm txoj hlua rau kev ua haujlwm. Cov yam ntxwv no ua rau kev tsheb ciav hlau hluav taws xob hloov tsheb thauj khoom siv dav hauv ntau qhov chaw muaj kev lag luam, tshwj xeeb tshaj yog nyob rau hauv cov xwm txheej uas yuav tsum tau siv cov khoom hnyav, xws li steel mills tuav steel, machinery factories tuav loj machinery qhov chaw, thiab lwm yam. cov nqi, thiab xyuas kom muaj kev nyab xeeb ntawm kev ua haujlwm.

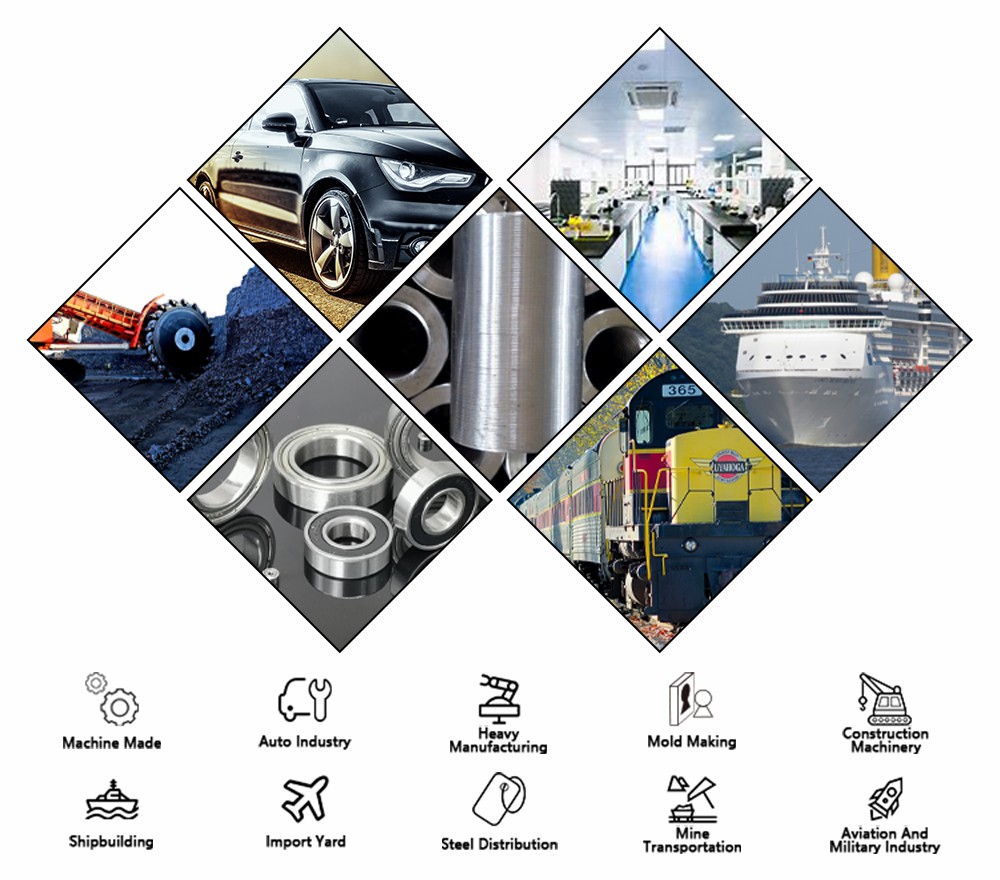

Daim ntawv thov

Daim ntawv thov scenarios ntawm kev tsheb ciav hlau hluav taws xob hloov tsheb thauj khoom suav nrog kev tsim khoom lag luam, warehousing thiab logistics, chaw nres nkoj terminals, mining thiab metallurgy, thiab lwm yam. Lawv tuaj yeem ua tau zoo thiab ua kom tiav tag nrho cov txheej txheem los ntawm kev thauj khoom raw mus rau cov khoom tiav tiav. Hauv kev lag luam xws li cov tshuab hnyav, kev tsim tsheb, thiab steel smelting, vim qhov hnyav hnyav thiab ntim ntau ntawm cov ntaub ntawv, cov txheej txheem kev tuav tuav tsis yog tsuas yog tsis muaj txiaj ntsig, tab sis kuj ua rau muaj kev phom sij. Rail hluav taws xob hloov tsheb thauj khoom tuaj yeem yooj yim daws cov teeb meem no thiab ua tiav cov khoom siv ceev thiab nyab xeeb. Tsis tas li ntawd, los ntawm kev txuas mus rau kev tswj hwm kev tswj hwm ntawm cov kab ntau lawm, cov tsheb ciav hlau hluav taws xob hloov tsheb tuaj yeem paub txog kev siv cov khoom siv hluav taws xob thiab ntse, ntxiv kev txhim kho ntau lawm.

Qhov zoo

Lub tsheb ciav hlau no ua haujlwm los ntawm lub nruas cable, thiab nws txoj haujlwm ua haujlwm feem ntau suav nrog cov hauv qab no: 1. Kev tswj kom nruj kom ntseeg tau qhov qub cua thiab siv cov cable; 2. Txoj kev winding, uas tuaj yeem ua tau dawb winding lossis ruaj winding; 3. Kev sib hloov ntawm lub nruas cable ua tiav los ntawm lub tshuab tsav xws li lub cev muaj zog lossis hydraulic; 4. Winding tswj, kho lub cable winding ceev, nro thiab winding kev taw qhia. Hauv luv luv, lub nruas cable ua tiav cable winding los ntawm kev sib koom ua ke ntawm ntau yam.