5 Ton Low Voltage Rail Coil Transfer Trolley

The working principle of the material handling vehicle is to realize free travel by laying low-voltage rails. A V-shaped frame is installed on the upper layer of the vehicle body to prevent the goods from falling during operation. At the same time, it also has the function of freely adjusting the size, which can adapt to the material handling needs of different sizes.

First, let’s understand the track laying of material handling vehicles. This kind of track generally adopts a low-voltage track power supply method, which can provide stable power support and ensure the normal operation of material handling vehicles. The low-voltage track can not only supply the power required by the vehicle, but also provide corresponding power for other equipment on the vehicle. This power supply method is both safe and reliable and can meet the needs of long-term work.

Secondly, the free-running characteristics of the material handling vehicle make it perform well in cornering situations. Compared with other handling equipment, material handling vehicles have superior maneuverability and can freely shuttle in small industrial environments. It has a small turning radius, can easily cope with complex working environments, and improves handling efficiency.

At the same time, the V-shaped frame design of the material handling vehicle is also one of its important features. This structure can firmly fix the goods and effectively prevent the goods from falling during operation. During the transportation of materials, slopes or bumpy roads sometimes occur. Without effective fixing measures, the goods can easily be affected or damaged. The design of the V-shaped frame can effectively avoid these problems and ensure the safe transportation of goods.

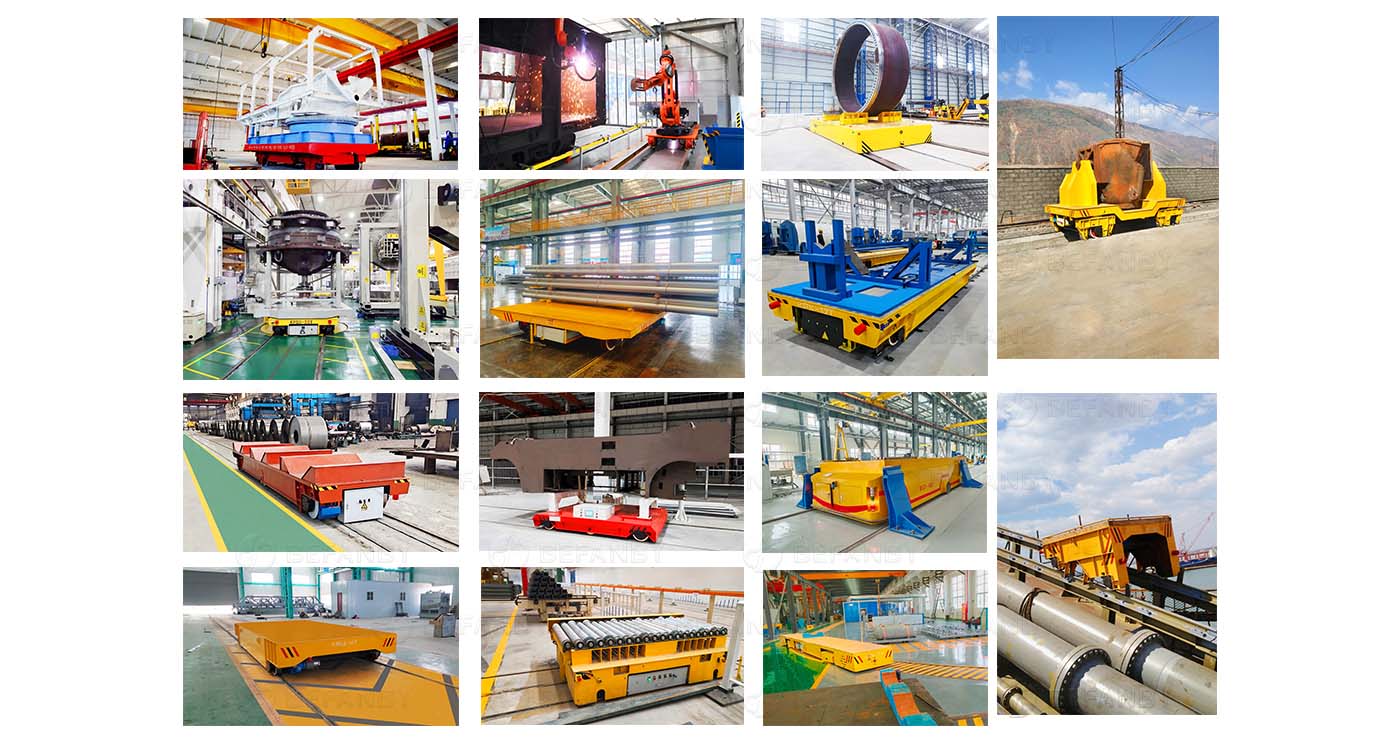

Material handling vehicles have a wide range of applications in various industries. Especially in manufacturing, warehousing and logistics, ports and terminals, material handling vehicles play an important role. It can help companies improve production efficiency, reduce labor costs, and ensure the safety of the handling process.

In short, material handling vehicles, as an efficient and safe handling tool, are increasingly being widely used by enterprises. Its working principle, characteristics and application scope make it an important part of the modern logistics industry. Whether in manufacturing or warehousing and logistics, material handling vehicles can play an outstanding role.